True multitasking. TECNOTRADE OBRÁBĚCÍ STROJE will showcase a Multi-Tasking Turning Center for Demanding Applications

August 21, 2025 / 1:15 PM

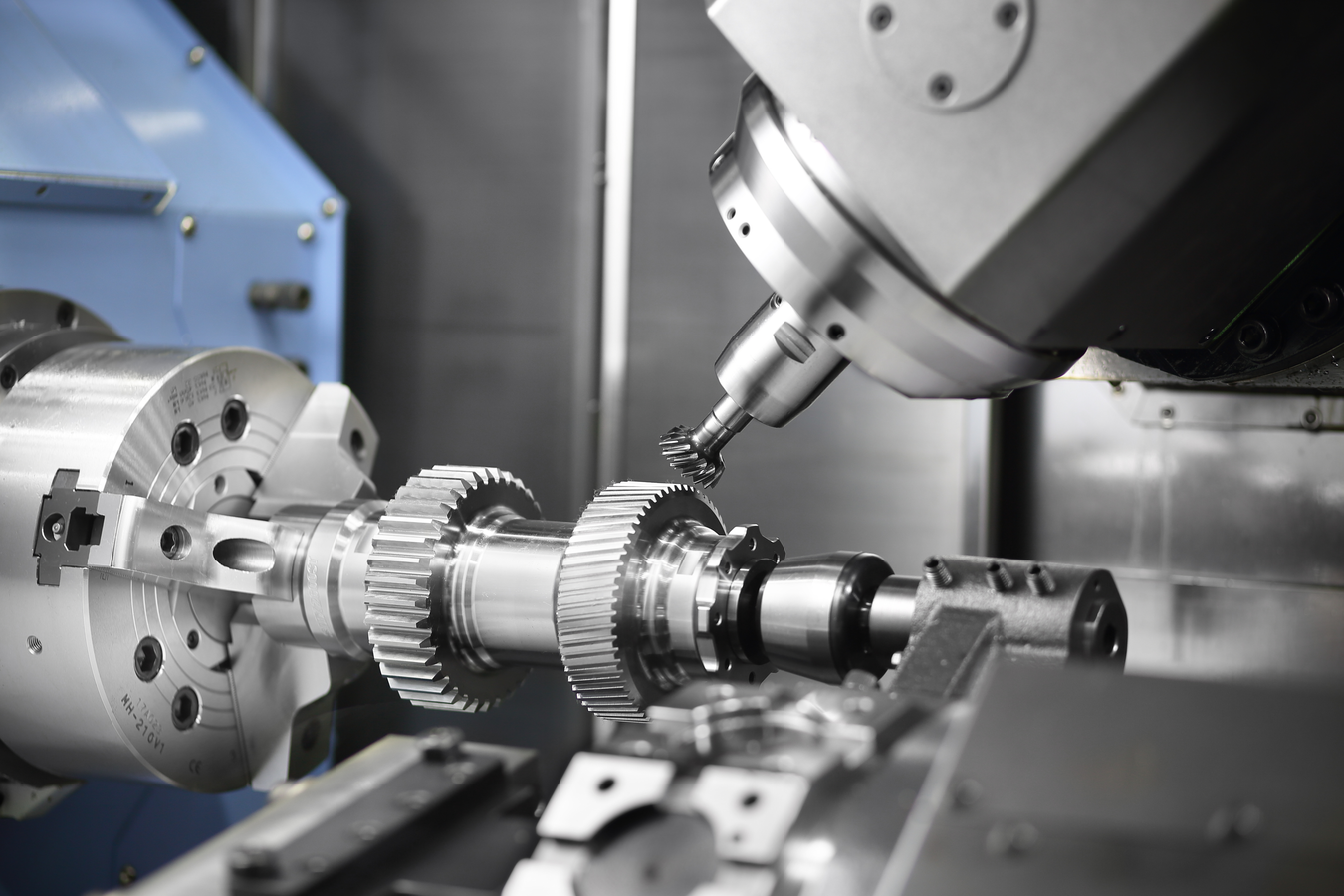

At MSV Brno 2025, TECNOTRADE will showcase a high-performance multi-tasking turning center SMX 3100ST.

SMX 3100ST – Advanced CNC Turning with Unmatched Productivity

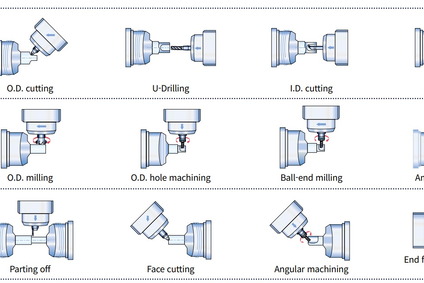

The SMX 3100ST is a state-of-the-art CNC lathe that combines turning, milling, synchronized machining, drilling, gear milling (including hobbing and power skiving), polygonal turning, and off-center interpolation turning with spindle indexing. This significantly reduces cycle times, setup operations, and workpiece handling, resulting in faster machining and maximum productivity.

Key Machine Features:

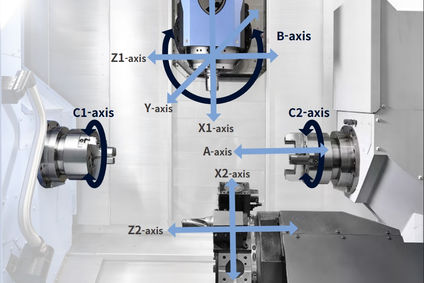

- Left and right spindles with high-precision C-axis indexing (0.0001°)

- 12" (15") chuck on the left spindle and 10" (12") on the right spindle

- B-axis milling head with ±120° rotation, precise indexing (step 0.0001°)

- 12 station servo-driven lower turret

- Extended Y-axis stroke – up to 30% longer than standard

- Maximum turning diameter: 660 mm

- Maximum turning length: 1540 mm — ideal for large and complex parts

- LM guideways ensure high rigidity and long-term precision

- Front-mounted tool magazine with intuitive control panel: 80 tools standard, optionally 120 tools

The displayed machine is equipped with:

- FANUC 31i-B5 Plus control system

- Optical scales on X/Y/Z axes

- Automatic machine shutdown function

- Tool measurement system for upper and lower milling heads

- Coolant and air blow-off gun for both spindles

- Automatic door opening system

- Lower turret steady rest preparation

✅ Key Advantages of SMX 3100ST

✅ True Multitasking

SMX 3100ST allows simultaneous machining on both left and right spindle. It supports operations such as drilling, threading, and face milling at any angle, precise angular machining, complex geometries via simultaneous 5-axis machining, and tailstock support using the right spindle or lower turret. This leads to higher productivity and reduced production time.

✅ High Precision and Repeatability

Thermal compensation, oil-cooled spindle (oil cooler) and ball screws, precise axis control, and a robust machine structure ensure excellent results even with complex shapes and demanding materials.

✅ Easy Operation and Maintenance

A user-friendly ergonomic control panel with swivel and height adjustment, intuitive interface, and a separate ATC control panel ensure operator comfort and ease of use.

Ideal for Demanding Application

SMX 3100ST is the perfect solution for companies that need to machine complex parts in small to medium series, particularly in:

- Aerospace, Energy sector, Automotive industry

- Mold and precision parts manufacturing

Visit them at MSV Brno 2025 and see the capabilities of the SMX 3100ST in action!

Booth No. 36 in Hall P.

The displayed SMX 3100ST will be offered at a special promotional price and will be available IMMEDIATELY after the event.