KAVON to launch special platform to support operators in industrial production

September 1, 2025 / 8:15 AM

KAVON supplies professional tools and technical solutions for industry and trade. At MSV 2025, it will present a platform to support operators in industrial production, which is a novelty not only in its portfolio but also in the entire country. It instructs the operator in real time and projects instructions directly onto the workspace.

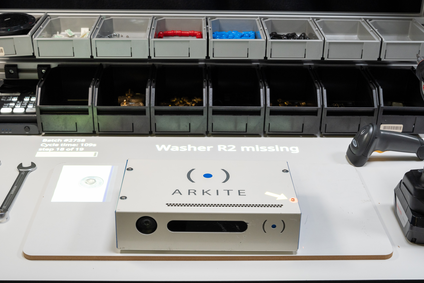

Arkite – Operator Guidance Platform

What is Arkite?

Arkite is an operator guidance platform for industrial manufacturing, using Augmented Reality (AR) to deliver digital work instructions directly at the workstation. This improves efficiency, reduces errors, and makes onboarding of new employees significantly easier.

Key features and benefits:

- Digital work instructions (text, images, video, GIFs) – displayed in real time, eliminating the need for paper manuals.

- Dashboarding & data insights – collects data on work steps, cycle times, and performance, with easy access through dashboards or export to MES/ERP systems.

- No coding required – fast configuration of instructions with intuitive software and structured version control.

- CAD/CAM support – projection of models in 1:1 scale, enabling digital workstation design based on 3D data.

- Pick-by-Light with DMX – alternative visual guidance using light signals for larger or more complex workspaces.

- Flexible production and variants – quick switching between product variants, barcode selection, and ERP/MES integration.

- Multilingual interface – work instructions can automatically switch into the operator’s nativelanguage, speeding up training.

- Integration with smart tools and systems – links with intelligent tools or PLC/SIM protocols to enable/disable tools depending on the production step.

Main advantages of deploying Arkite:

- Significant reduction of errors, rework, and complaints

- Improved consistency, quality, and production speed

- Faster onboarding and training, even for low-skilled operators

- Stronger reporting, traceability, and data-driven decision-making

- Flexibility for both serial and one-off production with quick product changeovers

Where Arkite is used

Industrial sectors

Arkite is widely adopted in several key industries:

- Automotive – used by manufacturers such as Ford and Bosch to support manual assembly processes, ensure quality, and enable Build-to-Order strategies.

- High-tech & electronics – ideal for detailed assembly and complex builds where operators must handle small, precise components.

- Aerospace, aviation & defense – supports operators in highly technical, precision-driven processes with validated assembly outcomes.

Real-world projects and case studies:

- PCB assembly (electronics) – At a global manufacturer, Arkite was deployed for PCB assembly. Results included: defect rate reduced from 0.12% to 0%, scrap reduced by 64%, training time cut by 50%, and assembly speed increased by 7%.

- Barco (high-tech) – Barco implemented Arkite with AR projection and a 3D sensor above the assembly station. Operators:

- Select the correct product from 14 variants

- Work faster with fewer errors

- Follow a standardized process independent of the operator

- Receive warnings or automatic tool deactivation when using the wrong tool or sequence

- Aerospace / space PCB assemblies – In aerospace, Arkite supports complex electronic assemblies with AR projection and sensors. Benefits included near-zero defects, elimination of paper work instructions, and faster onboarding of new operators.

Technological advantages and integration

- Real-time AR guidance – projects instructions directly into the workspace, eliminating the need for paper manuals.

- 3D Time-of-Flight sensors – validate steps by confirming that parts and tools are correctly placed and operations are performed in the right sequence.

- Smart Vision integration – infrared cameras check presence of small components (>0.5 cm), verify orientation of parts, and track tool usage.

- Easy MES/ERP integration (e.g., SAP ME, SAP ERP) – enables communication, tracking, validation, and automated process control (e.g., stopping the line).