PBT Rožnov p. R. will present technologies for the production of electronics with a high production mix.

January 26, 2026 / 3:08 PM

At the AMPER 2026 trade fair, PBT Rožnov p. R. will present technologies that enable a high production mix without compromising on quality. Visitors will learn about solutions for SMT placement, press-fit technology, and digital inspection used in modern electronics manufacturing.

For more than 30 years, PBT Rožnov p. R. has been one of the leading suppliers of electronics manufacturing technology in the Czech Republic and Slovakia. It will bring these interesting innovations to visitors at the AMPER 2026 trade fair.

RS-2 – flexible placement machine from JUKI

The RS-2 from JUKI is a highly flexible SMT placement machine that combines efficiency, accuracy, and a wide range of applications for modern electronics manufacturing. Thanks to its patented TAKUMI head, it can handle the placement of a wide range of components – from the smallest chips to large housings and connectors – without the need to change the head.

The RS-2 is the ideal solution for manufacturers with a high product mix who need to respond quickly to changing production requirements while maintaining stable placement quality and performance.

www.pbt.cz/cz/produkty/osazovani/osazovaci-automaty/rs-2

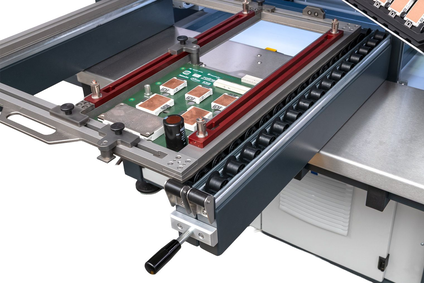

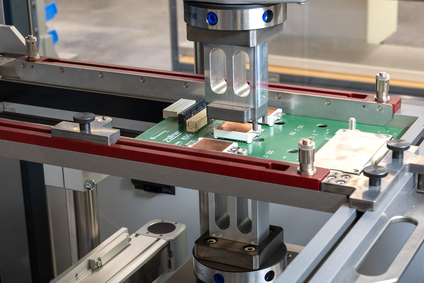

VERSAFIT ONE – new press-fit technology from Kurtz Ersa

VERSAFIT ONE from Kurtz Ersa is a new semi-automatic technology for press-fit mounting of components into PCBs, designed for medium-volume production with a high product mix. It combines high pressing accuracy, 100% process monitoring, and stable connection quality without thermal stress.

Thanks to its servo-electric pressing system, traceability support, and MES connectivity, it significantly reduces manual labor and increases production repeatability and reliability.

www.pbt.cz/cz/produkty/pajeni/press-fit-systemy/versafit-one

PROTEQ VISO – 3D digital inspection from Vision Engineering

PROTEQ VISO from Vision Engineering is a modern 3D digital inspection system that enables fast, accurate, and ergonomic inspection of electronic assemblies without the need for eyepieces. It offers a realistic 3D image with high resolution, great depth of field, and detailed display of even complex structures.

The system is ideal for PCB inspection, defect analysis, quality control, and manufacturing process documentation, helping to increase inspection reliability while maintaining a high level of operator comfort.

www.pbt.cz/cz/produkty/inspekce-mereni-a-testovani/digitalni-inspekce/proteq-viso