BIG DAISHOWA will present new clamping and boring systems for maximum precision at the trade fair

August 14, 2025 / 3:01 PM

Visitors to BIG DAISHOWA at MSV 2025 will discover a wide range of premium innovations for precise and efficient machining.

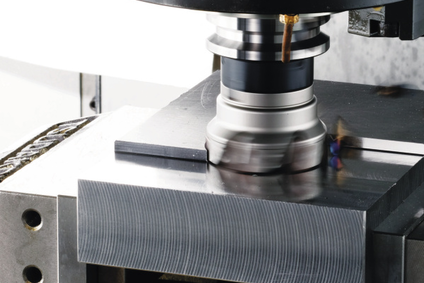

The MEGA New Baby Chuck line will be on display, featuring collet, ferrule, and body of absolute precision that exceed the performance of standard ER systems thanks to their reliable and improved concentricity.

Also featured will be a comprehensive portfolio of Hydraulic Chucks for 5-axis machining, delivering outstanding runout accuracy of max. 3 microns (measured at 4xD).

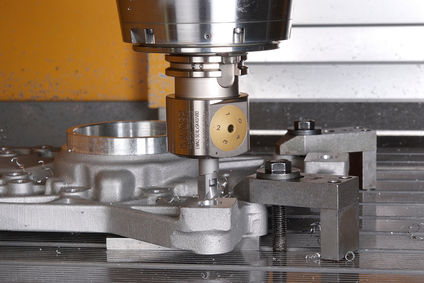

Attendees can explore twin-cutter boring heads SW, enabling two different roughing methods – RSS and DVS – without changing any components and without length adjustment.

The booth will also showcase Smart Damper anti-vibration products, designed for deep-hole boring with BIG KAISER’s CKB modular boring system, as well as for extended reach milling with both inch- and metric-pilot shell mills and face mills.

Visitors will see a complete tooling offer for machines with BBT30 taper, such as Brother or FANUC machines.

A highlight will be CKN – the strongest tool connection for lightweight boring tools, featuring a newly developed double connector coupling that allows the use of aluminum extension tubes, reducing weight by up to 50% compared to steel tool combinations.

Also on display will be Series 318, high-precision and lightweight boring tools made of hardened aluminium for diameters over 200 mm.

Finally, measuring instruments will be presented, supporting machine tool builders with machine servicing.