Beckhoff Automation to Showcase New Systems and Technologies at MSV 2025

September 19, 2025 / 11:30 AM

Beckhoff Automation is a leading manufacturer and innovator in the field of industrial automation. At MSV 2025, the company will showcase major innovations – from the extended MX-System for cabinet-free automation and new industrial PCs with Intel processors, to TwinCAT PLC++ software with AI integration, energy-efficient servo drives, and advanced measurement terminals. Visitors can look forward to innovative solutions that push the boundaries of industrial automation.

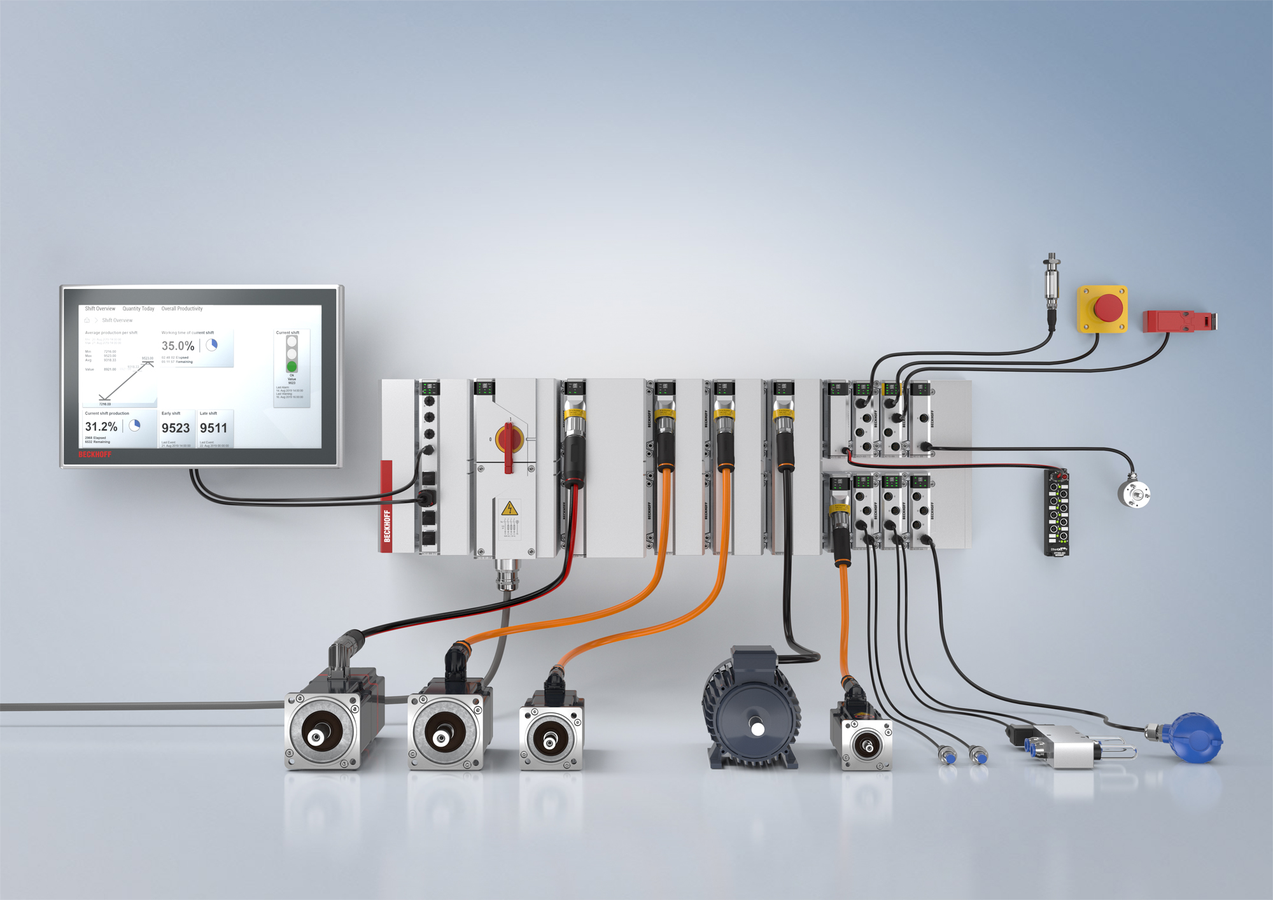

In 2025, Beckhoff Automation introduced several major innovations. In hardware, the company expanded its MX-System for control cabinet-free automation with new modules and performance variants, enabling the installation of control components directly on the machine. The industrial PC portfolio was expanded with models featuring the latest Intel processors and long-term support for Windows 11.

Another highlight is TwinCAT PLC++, the next generation of PLC systems offering higher performance and the ability to integrate AI functions. In motion technology, Beckhoff launched energy-efficient AX1000 servo drives and AF1000 frequency inverters. The company also introduced a new range of cost-optimized multi-touch panels and modern energy measurement solutions, such as the EL3475 terminal with direct EtherCAT network integration.

This year, visitors to Beckhoff’s booth will also see the XPlanar and XTS transport systems. XPlanar is a planar transport system offering free 2D motion with up to 6 degrees of freedom. Levitating planar movers float above individually arranged tiles, following freely programmable trajectories. Absolute flexibility in 6D product handling and 2D transport is achieved within one system. In addition, simultaneous control of multiple movers allows for parallel and individual product manipulation.

XTS is a unique linear transport system with a wide range of track geometry options. Each mover on the track is controlled as an independent axis. Movers can be freely grouped, positioned, and synchronized with one another. The main advantages of the XTS system are its simple and fast implementation, nearly unlimited variability to meet current requirements, and low operating and maintenance costs.