Bossard CZ: How to optimise and streamline production processes and reduce costs

July 22, 2024 / 12:19 PM

Bossard CZ s.r.o. is part of the international Bossard Group, one of the world's leading suppliers of fastening technology and logistics systems. With more than 190 years of experience and a global presence, Bossard focuses on providing innovative solutions for industrial manufacturers. Bossard CZ s.r.o. has been operating in the Czech Republic since 1992 and has become a reliable partner for many large industrial companies.

The company's main activity is the supply of high-quality fastening technology, solutions for optimising production processes and the implementation of logistics systems that increase efficiency and reduce costs. Its portfolio includes a wide range of products, from standard fasteners to customised solutions. Technical support and consulting are also an important part of Bossard CZ's services to help customers achieve the best possible results.

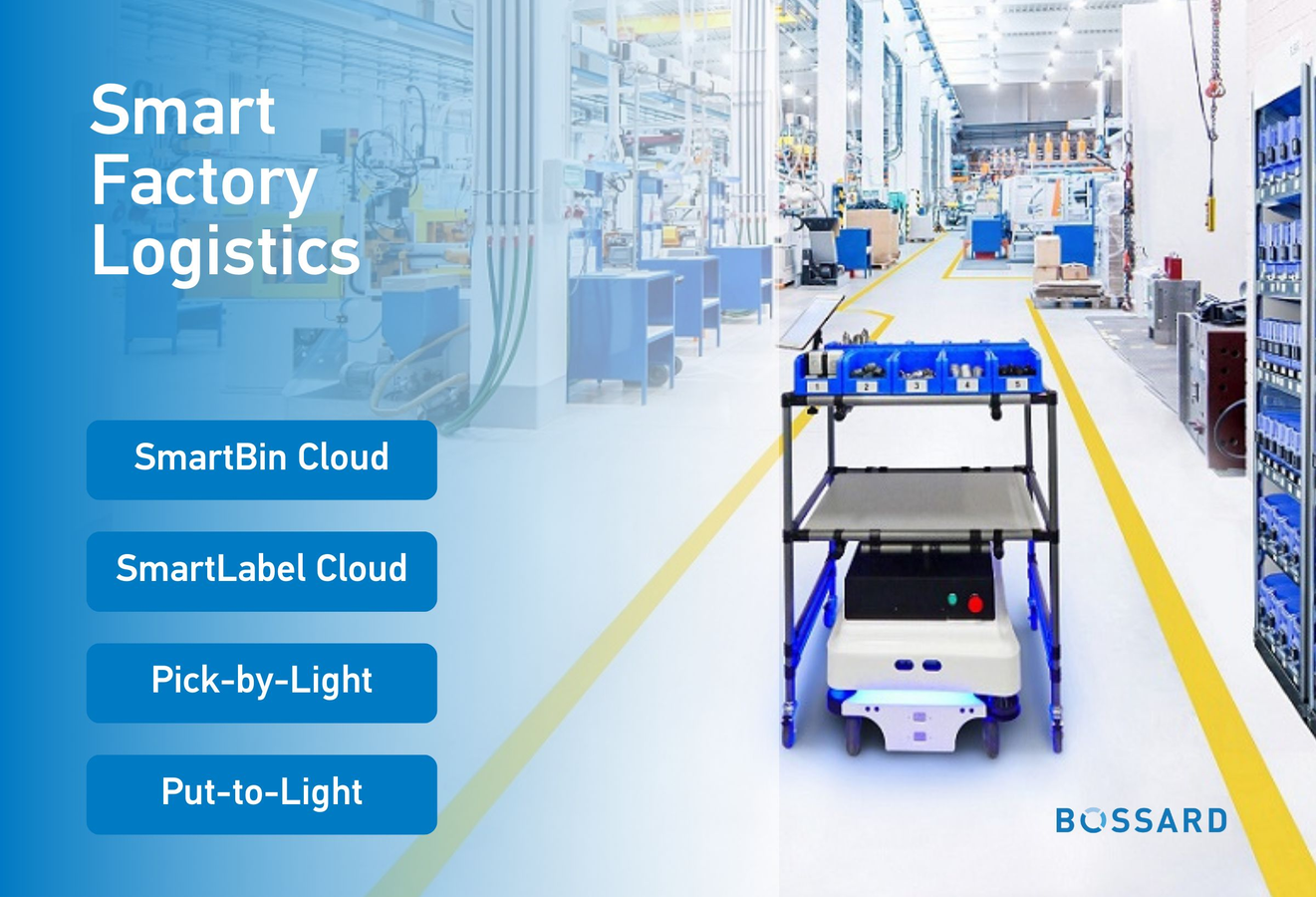

At this year's MSV, Bossard CZ will present Smart Factory Logistics systems and Smart Factory Assembly solutions at the Digital Factory stand (Hall F, Stand 202).

Smart Factory Logistics

The most commonly used systems in the Smart Factory Logistics range are SmartBin Cloud and SmartLabel Cloud. SmartBin Cloud is a fully automated weighing system that physically records stock levels and provides full control of the supply cycle within internal or external logistics. It is equipped with weighing, positioning and motion sensors. The motion sensor detects the removal or replenishment of components to/from the bin. Real-time inventory information is available for that workstation. The system automatically sends a replenishment order when the level in the box falls below a pre-determined level. The electronic display shows the current status of the order and the delivery date. All data is available and secure through industrial cloud connectivity and IIoT communications.

SmartLabel Cloud falls into the category of all-in-one modular logistics technology. It is a semi-automated ordering system with its own 2.6" electronic display, LED signage and pick-to-light technology. The long battery life (up to 5 years) ensures minimum maintenance and maximum reliability. And how does it all work? At the point of use or in the warehouse, the operator needs to replenish the items in the box. He presses the order button on the label and sees the entire progress of the order in real time, including the delivery date. Once the item has been added to the appropriate box, the operator briefly confirms this delivery by pressing a second button and the order is successfully processed. The Bossard CZ stand will feature live demonstrations of this system in action to give visitors an insight into its benefits and functionality.

Smart Factory Assembly

Smart Factory Assembly is a comprehensive solution for automated assembly in industrial plants. It consists of several devices and technologies that communicate with each other to improve efficiency, assembly quality and speed up the training of new operators on the shop floor.

One of the key elements of Smart Factory Assembly is the aforementioned SmartBin system, which enables automatic replenishment of tools and other materials directly on the production line. This system is linked to a central control system and sends real-time inventory information to plan and manage assembly processes.

Another key feature is robotic assembly, which allows some parts of the assembly process to be automated. The robots are programmed to accurately and quickly assemble complex products without the need for manual operator intervention.

Smart Factory Assembly also includes data tracking and analysis equipment to help identify problems in the assembly process and optimise performance, thereby improving production efficiency.

Overall, it is a sophisticated solution that improves work efficiency and quality, speeds up the training of new operators and increases assembly safety in industrial plants. This system enables industrial companies to achieve higher levels of automation and improve their competitiveness in the market.

Visitors to this year's MSV will have the opportunity to experience this solution through an interactive station located directly on the Bossard CZ stand.

In addition, this year's Digital Factory will showcase some of our specialist products, including special fasteners and solutions tailored to specific applications and customer requirements. Visitors will also have the opportunity to try out our Smart Tools, which are designed to increase the efficiency and accuracy of assembly operations.

The Bossard CZ representatives look forward to welcoming you to stand 202 in Hall F and believe that their solutions will contribute to your success in industrial manufacturing.

Web and social media:

https://www.bossard.com/cz-cs/

https://www.linkedin.com/company/bossard-esk-republika/posts/?feedView=all