BJ Energy: Robotic welding, CNC machining, and laser cutting

September 3, 2025 / 3:00 PM

BJ Energy, s.r.o. is an engineering company specializing in the production of technologies, parts of technological lines, various welded assemblies, and conveyor systems. These are manufactured either based on supplied production documentation or on designs developed by our engineering team. At MSV 2025 BJ Energy will present

BJ Energy employs state-of-the-art technologies and processes, including in-house CO laser and waterjet cutting of flat materials, conventional and CNC bending, and certified MAG and TIG welding. We also offer CNC machining, laser cleaning, blasting, and industrial painting. Supporting operations such as thread cutting, conventional machining, hydraulic punching, and profile rolling are also part of our services. At every stage, the BJ Energy team ensures projects stay within budget while maintaining the highest standards. Our experienced, highly qualified, and certified professionals guarantee fast and high-quality delivery.

BJ Energy holds a wide range of top-level certifications for its operations across various markets:

Integrated Management System (IMS):

- STN EN ISO 9001:2016

- STN EN ISO 14001:2016

- STN EN ISO 45001:2024

Welding Certifications:

- EN 15085-2 CL 1 (since 2022)

- EN ISO 3834-2 (since 2021)

- EN 1090-2 EXC-4 (since 2019)

- EN 15085-2 – European Committee for Welding of Railway Vehicles (ECWRV)

- Welding Procedure Qualification Record (WPQR)

- Cutting Procedure Qualification Record (CPQR)

- Development of Welding Procedure Specifications (WPS)

The strategic location of our production facility in Veľká Lomnica allows us to serve not only regional clients but also customers around the globe.

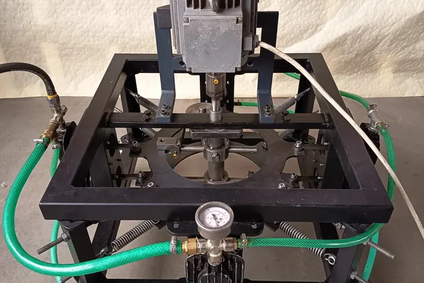

Importrant product at MSV 2025

BJ Energy will present a patented Vibrational Compressor (Patent No. 288877) at the trade fair, which it exclusively manufactures. The device operates on the principle of centrifugal force acting on weights attached to active components of the system, such as compressor pistons, pump diaphragms, or generator cores. During rotation, these weights are pushed outward from the center due to the centrifugal force. This motion is transmitted via connecting rods to the working elements, resulting in the performance of mechanical work with exceptionally high efficiency.

This technology, based on a fundamental physical principle, represents a revolutionary approach to powering mechanical and electromechanical systems, offering significant improvements in energy performance. By adjusting the circular path and rotational speed, the system can be optimized for a wide range of applications in industry, energy production, and transportation. Key advantages over traditional drive systems include:

- Efficiency increased by several dozen percent

- Reduced energy consumption under load

- Non-linear power amplification

- Potential for energy output to exceed energy input

Website: https://www.bjenergy.eu/

Facebook: https://www.facebook.com/profile.php?id=61558752680294