4dot: Process Monitoring and Machine Diagnostics

August 26, 2025 / 8:30 AM

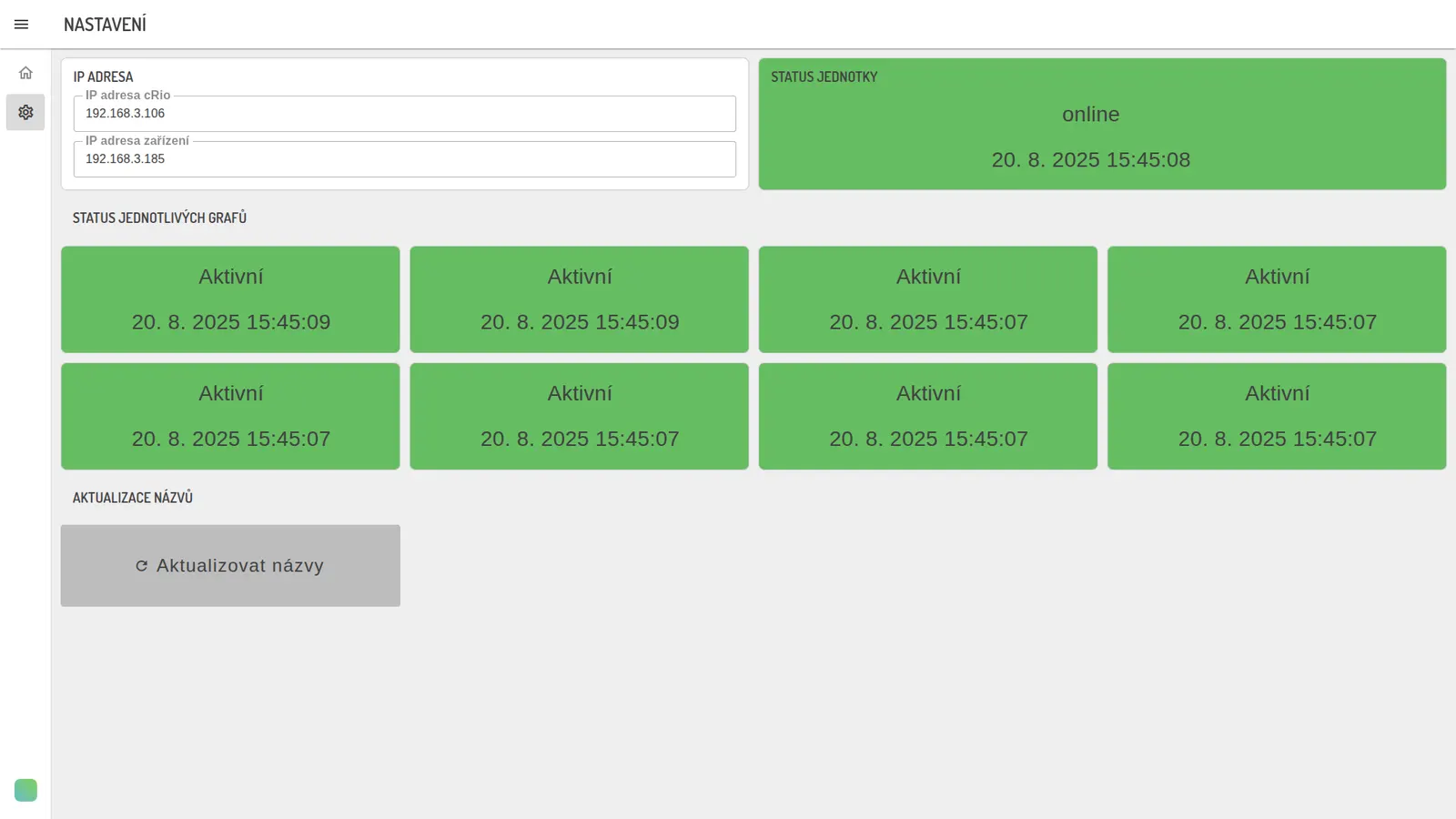

Thanks to in-house sensors and patented technologies, the startup 4dot has become an innovator in process monitoring and technical diagnostics. Its solutions deliver higher production quality, tool protection, and predictive maintenance. Meet them at MSV 2025.

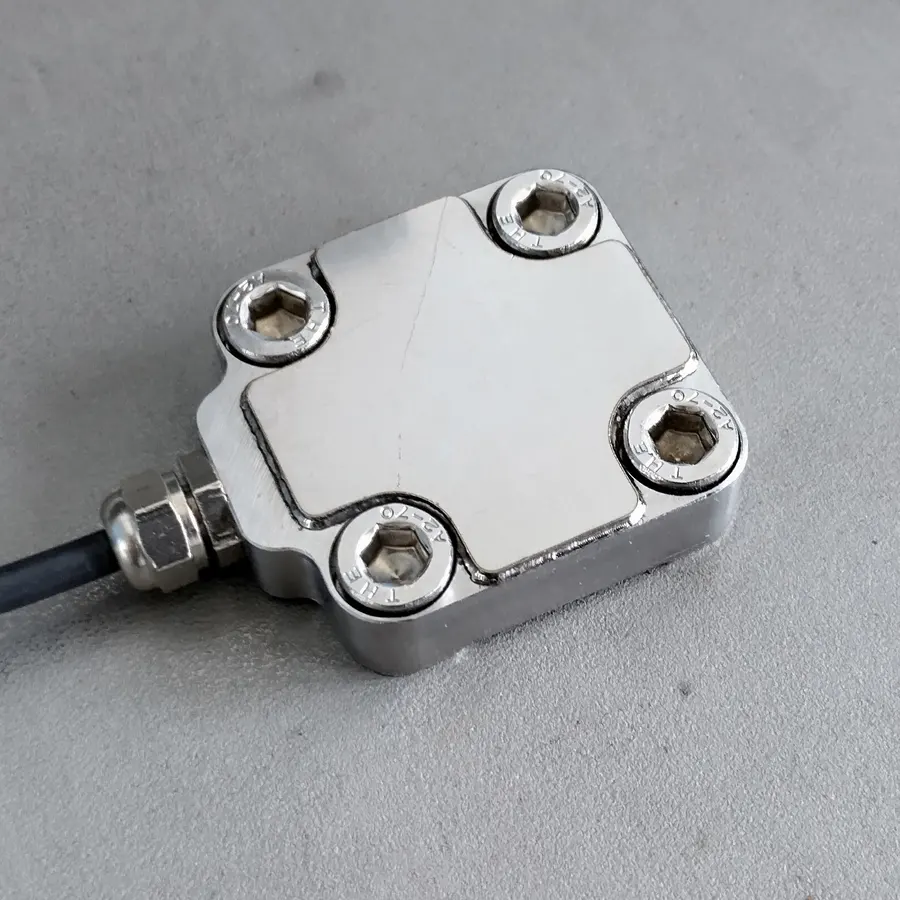

4dot is an independent Czech startup developing technologies and providing services for technical diagnostics and process monitoring of machining and forming machines. 4dot manufactures its own vibration and deformation sensors and offers measurement and specialized engineering services. Thanks to patented analyses, sensors, and unique know-how in engineering and mechatronics, 4dot can gather valuable information even in areas where standard sensors cannot be placed and camera systems cannot be used.

At MSV Brno, 4dot will present the Rarog display panel, which significantly expands the capabilities of the monitoring unit, particularly in process monitoring. The panel is named after the Slavic mythical firebird Rarog, which can rise from its own ashes.

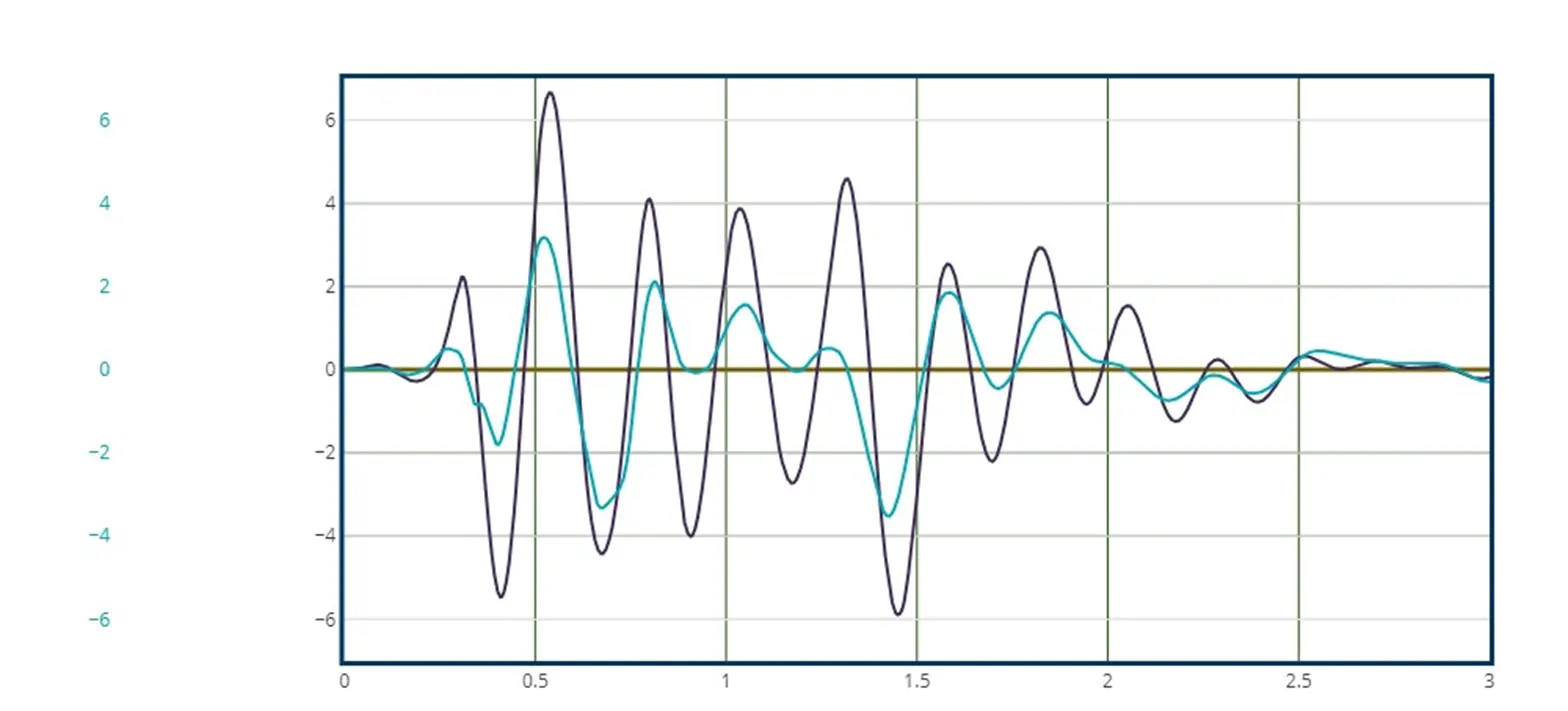

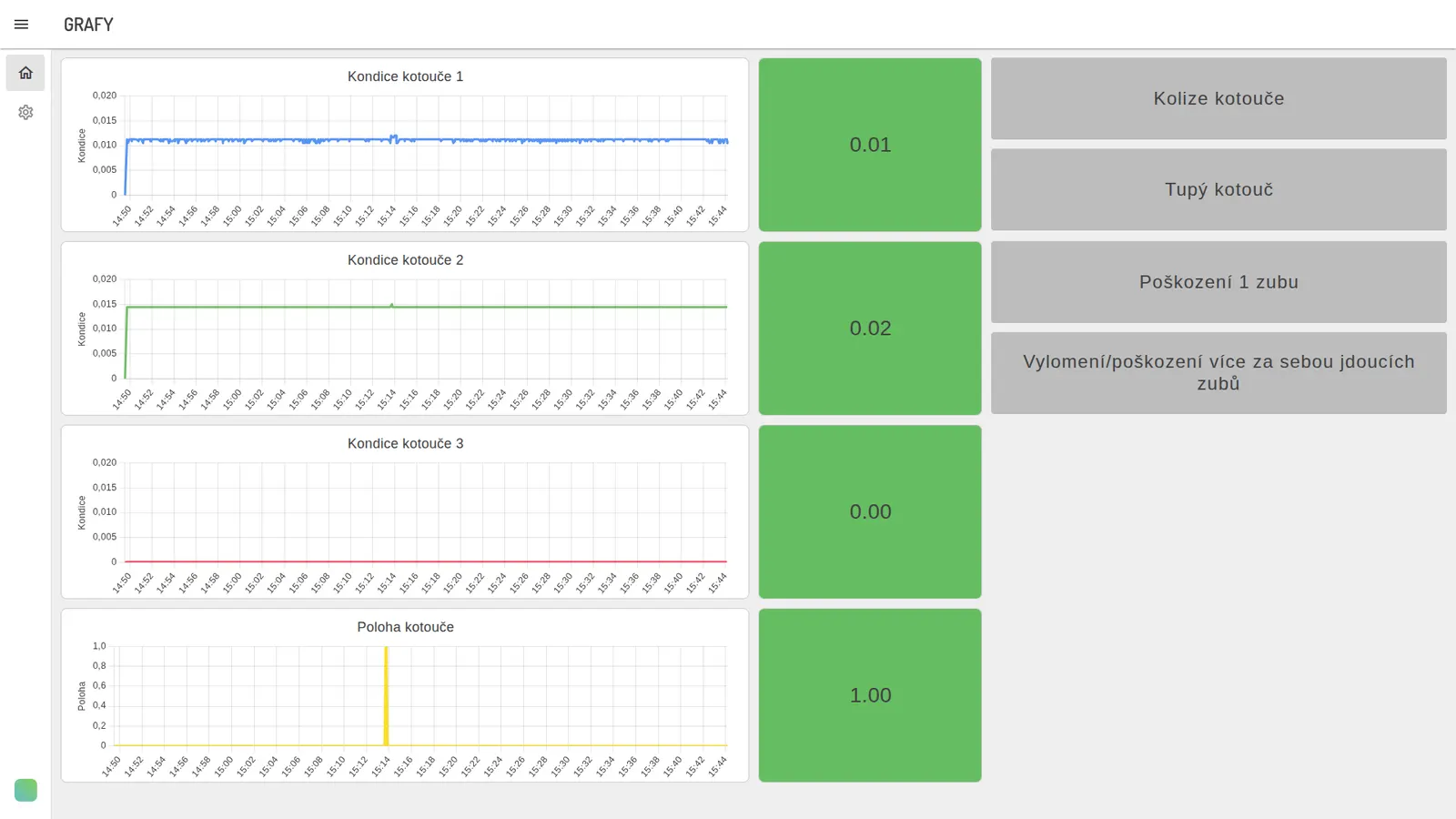

Process Monitoring

Real-time monitoring of processes, quality, and tools.

|  |

Bulk Forming

Process monitoring in bulk forming ensures product consistency and prevents tool failures. The 4dot system is suitable for single-operation and progressive presses and monitors production even during ramp-up and ramp-down thanks to handling boundary conditions. It tracks force progress, tool condition, and the entire forming process, protecting the machine from overload and detecting wear or process errors.

Sheet Forming

Tool protection during pressing is ensured by maintaining precise forming parameters. The system monitors lubrication, smooth operation, pressing force, and the movement of the tool components, detecting deviations early and ensuring high production quality.

Machining

4dot process monitoring enables timely tool replacement, stops machining in case of insert damage, detects collisions, and tracks tool–workpiece contact for adaptive machining control. The system evaluates forces and analyzes the machining process in detail and is suitable for both turning and rotary tool machining.

Grinding

4dot process monitoring tracks workpiece geometry, tool condition, and grinding intensity in real time. By evaluating the material removed, it ensures precise surface control even for critically stressed components such as rolling bearings.

Technical Diagnostics

Regular data collection, large volumes of data, and the ability to react instantly.

|  |

Bearings

Monitoring bearing condition increases machine availability, extends the life of key components, and reduces maintenance costs. Patented 4dot MUSA analyses allow monitoring of both low-speed and high-speed bearings and are not limited by speed or machine type.

Non-Rotating Components

Continuous condition monitoring allows for planned maintenance and increases machine availability even for non-rotating parts. Patented 4dot technologies extend predictive maintenance capabilities and enable the monitoring of ram clearance, linear guides, tool deformations, and machine frame integrity.