LAC, s.r.o.: Advanced Heat Treatment Solutions for Defense, Aerospace & Industry

May 23, 2025 / 1:15 PM

Art of heating – trusted manufacturer of industrial furnaces, dryers & thermal processing systems since 1992.

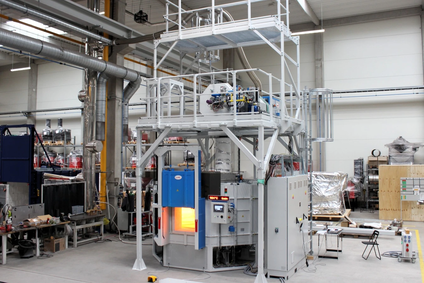

Founded in 1992 in Židlochovice, Czech Republic, LAC, s.r.o. has grown from a small garage operation into a global leader in industrial furnace manufacturing, with over 20,000 furnaces delivered worldwide and a workforce of more than 220 employees. It specializes in furnaces, dryers and custom heat treatment solutions for the defense, aerospace, automotive industries and also supplies furnaces to a wide range of other sectors (mechanical engineering, rubber industry, additive manufacturing, laboratories, ceramics). A significant activity of the company is the production of refractory castable shapes, part of which is used in its own production of industrial furnaces. Other customers are companies from the metallurgy, energy and manufacturers of wood, pellet and biomass boilers.

Key Milestones

- 1990s: beginnings of production with a focus on ceramic furnaces, later expansion into the refractory materials and industrial furnaces industry

- 2000–2010: pioneer in the supply of low-temperature chamber furnaces SV line and wagon chamber furnaces SVK line designed for artificial aging of large components made of aviation aluminum alloys with an accuracy of ±3 °C

- 2010–2018: first energy audits of holding and melting crucible furnaces for aluminum alloys, energy-efficient holding crucible furnaces PTE Mk.II line are launched on the market

- 2018: opening of the furnace and drying plant on an area of 8,400 m² is an important step for the design and production of large custom projects including robotized hardening lines and continuous furnaces

- 2024: new facilities for the production of refractory concrete parts – strengthening synergies between furnace technologies and material development

Defense & Aviation: Precision under pressure

LAC’s furnaces are critical to weapon systems, artillery shells, and aircraft components, combining automation with stringent military standards:

- Fully automated, robot-operated lines for hardening artillery ammunition, consisting of car-chamber furnaces and hardening baths.

- Continuous furnaces for annealing cartridge cases, curing composite parts, and curing potting compounds on electrical components.

- Carousel furnaces for annealing foundry molds for precision investment casting

- Chamber and bogie-hearth furnaces for preheating titanium semi-finished products, heat treatment of welded joints of axles and parts of combat vehicles, sintering of parts manufactured by additive technology

- Low-temperature furnaces for artificial aging of composite materials, polymer drying, preheating of polycarbonate

- Furnaces for chemical-thermal treatment, teniferation of metal parts of weapons, surface treatment of weapon components

- Furnaces for repair plants, service and maintenance of weapons

- Furnaces meeting CQI-9, AMS 2750 standards and NADCAP accreditation

- Melting crucible furnaces for foundries

Industrial Versatility: Broad application range as a competitive advantage

LAC furnaces cover 40+ industries from automotive to ceramic industry. 52 type series of standard furnaces and dryers together with a focus on custom production (up to 6 custom projects per month) can satisfy any specific needs and requirements of the customer at competitive prices. Our own development and design office together with a team of service technicians are a guarantee of quality services for customers.

Conclusion: Heat treatment, redefined

With 30+ years of innovation, LAC, s.r.o. bridges tradition and cutting-edge technology, ensuring reliability for the defense sector while driving efficiency across industries. Their customizable, certified solutions position them as a trusted partner for mission-critical thermal processing.

Explore more: www.lac.cz | Contact: +420 547 230 016